When Should I Refit A Boat?

With a good plan, a refit isn’t as complicated as it may seem. Know what you’re getting yourself into.

When the market loses stability, buyers resort to safer pastures. No surprise there. Smarter budgets, more recognized brands, and a little patience become cornerstone to decision making. For those seeking a value play, a “fixer upper” boat refit might have the most upside, but what are you risking? Refits can be complicated; diagnosing issues, finding trustworthy contractors, locating parts and dealing with weather are all daily stressers. No one wanted to deal with those headaches in the post-covid boom, but now, the potential upside is attractive.

With increasing market volatility and record high MSRP pricing, crafty clients are turning to refits to create equity. If you’re one of those people, I hope this article helps you plan the journey. Read to the end for a free download of our company’s project management spreadsheet.

It’s important to note our definition of “full refit” means a significant workload, but doesn’t necessarily mean the boat was rebuilt “soup to nuts”. The actual full refit workload varies project to project.

Why Refit?

A rare few enjoy ripping apart a boat and putting it back together. Assuming you’re not one of those people, here’s a few reasons to take on a refit opportunity.

Limited Inventory / No Matches.

When the market is scarce with your preferred model, the only remaining options are likely overpriced (on the high end) and beat up (on the low end). If you can refit a beat up option to your liking and your total spend doesn’t overcome the fair market value, you’ve manufactured the perfect boat at the right price.

You’ve Got Unique Needs and DON’T WANT TO BUY NEW.

As MSRP’s continue to rise, refitting a used option with today’s technology and your favorite features will be significantly cheaper. You might be able to get those custom features with a new factory order, but you’ll pay premium prices and cross your fingers your requests come as expected.

Seller Tired of A Broken Boat.

Tends to happen more frequently with trendy brands. New boaters buy in and don’t realize what’s involved in boat ownership. Over time the boat misses maintenance and things deteriorate. As long as rehabilitation is attainable, this is the most opportune refit opportunity. All beat boats aren’t created equal. For a simple refit, stay away from boats with significant water intrusion and older European builds requiring an electrical conversion.

Refitting a VanDutch? Two notes…

We’ve recently done refits on two VanDutch 40’s using our three-phase system. Keep two points in mind while strategizing your VD refit.

VanDutch is an easy refit when dealing with certain model years.

VanDutch is a network of accessible analog systems stemming from a straightforward electrical circuitry, surrounded by dependably laid fiberglass. Pretty simple. Any of the US-built hulls (c. 2014-2018) should use American parts or parts native to the American marine industry.

Refits are time sensitive, even when you’re not in a rush.

Planning and logistics are just as important as work quality. Parts are hard to find depending on your model year, sometimes backordered from overseas. With parts and services in limited supply, scheduling work comes together like a puzzle, and that puzzle may only have one right answer. Wait time can cost big bucks, so have your planning in place before you hit the GO button. Don’t commit dollars to the project until every task is timed and quote.

3 questions to answer before starting

Before committing to a refit, ask these questions to paint the full picture. Without answering these questions, you might get yourself in an expensive mess.

Is this a passion project or a profit play?

This defines your budget strategy. If you’re looking to create equity, your decisions on parts and time allowance should be drastically different than if we’re building your dream boat. While budgets can get out of hand, a professional knows the total project cost within 5-8%.

Where are you doing this work?

Location is a focus for two reasons: fees and weather. Location fees are popularly forgotten: yard fees, storage costs, haul and block, and transportation costs to and from the refit location should be pre-planned. Weather is impossible to plan, but as an example, outdoor refits during hurricane season in Florida are a major mistake!

What is your true timeframe?

Here’s the best advice you can get: Do not let your timeframe be the primary factor of refit planning. Your project needs attention, and you should prioritize improvements instead of forcing a convenient completion date. I.e.: “Summer starts in 4 weeks. I need it done by then!”

Now, if you’re working with someone experienced, time calculations are fairly accurate. If not, do yourself a favor and add 25% more time than initially expected. Make sure you include time for testing your boat in the water for a few days before proclaiming the job complete. The last thing you want is a costly return to the shipyard because something isn’t right.

DIY refit? Here’s what to look out for

Availability of Parts

If you have yet to purchase your boat, consider the builder’s historic parts trends before making your final purchase decision. Don’t assume the parts you’ll need just because you’ve seen them elsewhere on the same model. We check parts and availability before taking on a project. A boat with some ugly fiberglass repair may be a more attractive project than a boat with existing expensive upgrades you won’t be able to find parts for.

“Sitting” Cost

This one is easily overlooked. How much will it cost you to leave the boat somewhere while the work is done? How will parts and labor delays affect your Sitting Cost? If you’re outside, bad weather becomes a costly factor. Working inside is a luxury, but space is limited, costly, and more available for smaller boats. We target rates inside warehouses between $30-40/ft/month and only bring the boat outside to paint.

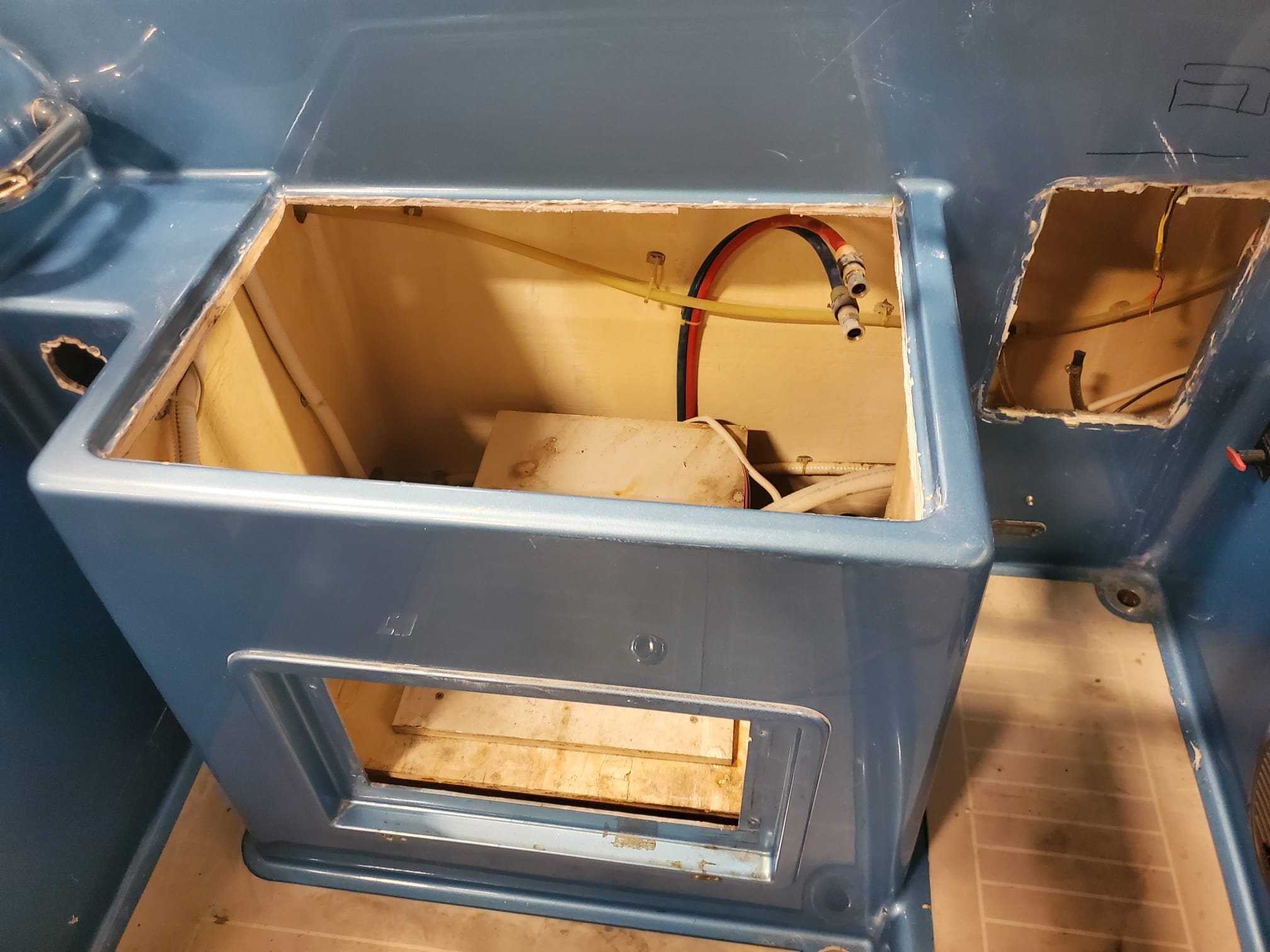

Access is Everything

Your costs will depend on two factors: the cost of the part(s) and the cost of labor to install said parts. Just because a part is $10 doesn’t mean its cheap to replace. That simplicity will depend on your accessibility to the “replacement zone”. Know exactly how you will access the “replacement zone” before starting a project. There is nothing worse than cutting through your boat only to be surprised by walls or parts impeding your access.

For My VanDutch Refitters: Accessibility to vital VanDutch areas is high, especially when you’ve got the boat disassembled and ready for paint. Pre-paint is always the cheapest time to rewire and replace.

Electrical Conversions

Im not a fan, but I know people who take it on. When it comes to day boats, especially older ones, electrical conversions can be detrimental to your mental health. You’ll try to upgrade one thing, then another, then you’ll be rewiring the whole boat before you know it. I’m being dramatic, but if you’re refitting a day boat on a budget I would stay away from boats requiring electrical conversions.

Do’s And Don’ts

DO add value through these universally beneficial improvements.

DO: Proactively Address Alarms

What sets off alarms? Start there: Engines, generators, fuel systems, bilge pumps, float switches, fire systems, sensors, battery banks, corroded wires, cooling fans and filtration. I’m sure there’s more, but that’s a good place to start.

DO: Clean Up Cosmetics

I’ve been selling boats for a while and scratches are the #1 reason prospects get turned off. Not because they are detrimental to the boat, but because its the easiest issue to call out. For these reasons, we make sure cosmetics are the second focus after our alarms are addressed. Its obvious, but in terms of creating a refit protocol, its important to note. The most important cosmetics to buyer prospects include paint, flooring, upholstery and ceiling liners.

DO: Address What’s Needed

When you hear the term ‘fully refit’, I’m sure they think the boat was completely rebuilt, soup to nuts. When I reference a ‘full refit’, I only mean those things that needed refitting. Need, in this context, is subjective to the client, but the important lesson is not to complicate things. Don’t overengineer the project. Get in, get out, get cruising.

Do’s and Don’ts

DON’T risk these empty value options unless they are personal interests.

DON’T: Pay for carbon fiber accent packages (non-performance based)

DON’T: Overpower and overengineer a sound system

DON’T: Install excessive screens (chartplotters and engine monitors)

DON’T: Use luxury fabrics and upholstery materials

FREE FILE DOWNLOAD

RN Marine Project Management Template

Our refit management template uses a budget calculator, parts tracker, and Gantt chart scheduler to keep our team on track. Download the file FREE by signing up for the RN Marine Newsletter and the file will be emailed to you.